So far I’ve written few articles on environment friendly course of monitoring, making the case that third-party monitoring is actually probably the most robust alternative for finishing up this. That talked about, I’m undecided if I’ve conveyed how important it is to also have a real-time production-monitoring system. Ideally, it must be a producing execution system (MES) that may be utilized along with course of monitoring.

At a earlier agency, I was part of a crew tasked with determining and effectively integrating such a system into the operation. This column will hopefully make clear my thought course of, and what I was looking for within the form of system to every deal with manufacturing and provide environment friendly course of monitoring. I’ll moreover share a number of of the roadblocks it’s possible you’ll face with the form of enterprise, or not lower than what I and my crew have been able to current choices for.

Discovering the Most interesting Match

Whereas working as technical shared service supervisor inside the medical side of our enterprise, I was tasked with determining a real-time manufacturing monitoring system—the aforementioned MES. This course of had been tried many situations by means of the years at this facility and had commonly hit roadblocks due to packages falling wanting providing what everyone inside the facility wished. Many packages had been proposed to the administration workers, and every was shot down because of none of them met everyone’s expectations or requirements.

I didn’t want this enterprise to stall within the an identical method earlier makes an try and introduce monitoring to this facility had petered out.

The very very first thing I noticed was that no out-of-the-box system would be good for everyone, however after we may set up a system that is perhaps custom-made, we would in the end get there. The target of the enterprise must be to allow all departments to produce enter on the deliberate system. That talked about, you can’t allow pushback from others to stall the enterprise each. When this happens, it is advisable to be ready to determine that might not be trendy with everyone nonetheless is vital to take care of the enterprise going.

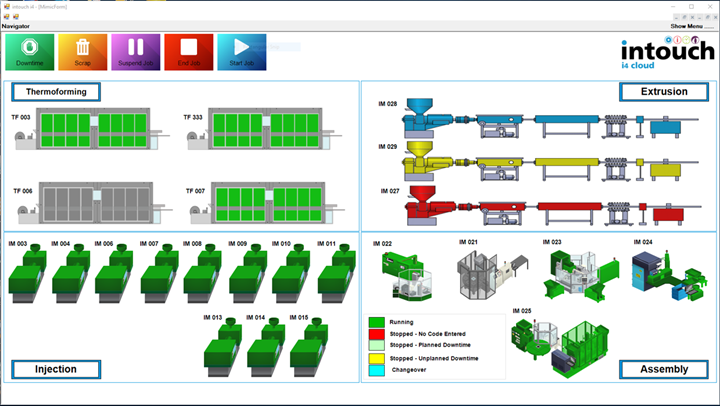

The Intouch production-monitoring program gives a dashboard view of a plant for a quick overview of a facility.

Perception me, I had my share of those decisions to make, and I knew the target may very well be to each modify the system or modify our manufacturing procedures, as wished, to most interesting benefit from its capabilities. So, not exactly ignoring my colleagues’ needs or concerns, nonetheless considerably understanding that the system or the company may evolve to fulfill them in the end. I didn’t want this enterprise to stall within the an identical method earlier makes an try and introduce monitoring to this facility had petered out.

Course of Monitoring as an Afterthought

A majority of the packages that had already been considered at this facility have been predominantly production-monitoring packages that occurred to have some process-monitoring capabilities. Considering that my background has almost solely been in scientific injection molding, I the truth is prioritized course of monitoring as an important system requirement.

The problem I had with a majority of the production-monitoring packages within the market was that their process-monitoring capabilities have been almost an afterthought. It’s a good time to degree out that the system that was required for this particular molder wished to have the power to current environment friendly third-party course of monitoring to carry out considered one of many main goals I had set for the enterprise.

As a result of the injection molding course of itself is part of the medical molding qualification, verification of the strategy is required all by means of a producing run. The current observe on the time was for a course of technician to doc the licensed course of outputs 4 situations a day on a cycle pointers. This meant that definitely considered one of our extraordinarily educated technical sources was spending time doing fill-in-the-blank paperwork instead of utilizing his expertise set in further value-added actions. On prime of this, typographical errors may result in important waste. If the strategy technician accidently wrote down a 9 instead of a six on this cycle pointers, it’d merely result in parts being scrapped going once more to the sooner accepted entry.

Inside the medical molding enterprise, we couldn’t rely solely on verification of the half’s sort, match and efficiency to launch product. We wanted to indicate we had produced the parts contained in the verified course of limits. To take away what lean manufacturing would search recommendation from as “Skill Waste,” the process-monitoring system ought to be able to independently seize these outputs. In addition to, it ought to be able to segregate a shot that did not fall contained in the accredited administration limits and have the ability to interrupting the machine cycle if the number of segregated photos exceeded a predetermined threshold prohibit.

Manufacturing-monitoring corporations are consultants in MES packages nonetheless not usually consultants in injection molding.

A large lesson I noticed was the importance of rising important requirements for the system upfront alongside together with your crew based totally on the operation’s current procedures sooner than starting to think about potential monitoring packages. That’s when it pays off to have enterprise crew members who actually perform the job. They’ll current particulars that are usually missed by people who aren’t hands-on. As far as system requirements go, evidently in case your purchaser doesn’t require the form of course of verification, the process-monitoring requirements couldn’t have to be totally unbiased of the machine’s native process-monitoring capabilities.

If this is so, requirements in your operation is perhaps decreased to a system that makes use of the machine’s monitoring capabilities and permits for the presses to be networked into the system. That talked about, understand that environment friendly process-monitoring packages are superior packages that require course of, machine and mold expertise to develop. Manufacturing-monitoring corporations are consultants in MES packages nonetheless not usually consultants in injection molding.

This was evident when reviewing each system’s capabilities. Companies that tried to produce a “jack of all trades” product, often fell wanting being most interesting in class in one thing. That’s my opinion, and I am going to say that there are packages within the market which have launched inside the obligatory expertise set to boost course of monitoring, nonetheless they’re miles behind enterprise leaders in environment friendly course of monitoring.

It grew to turn out to be apparent early on inside the enterprise that if the system was going to look at an injection molding course of efficiently and deal with manufacturing efficiently, we wished to look proper right into a system for each, instead of an all-in-one technique. After I first actually useful this concept, it was fairly controversial. Fellow managers launched up concerns about getting crew members to make use of 1 system, to not point out two, which is a official fear. It does not matter what system you establish on, if it is not used, it is worthless to you.

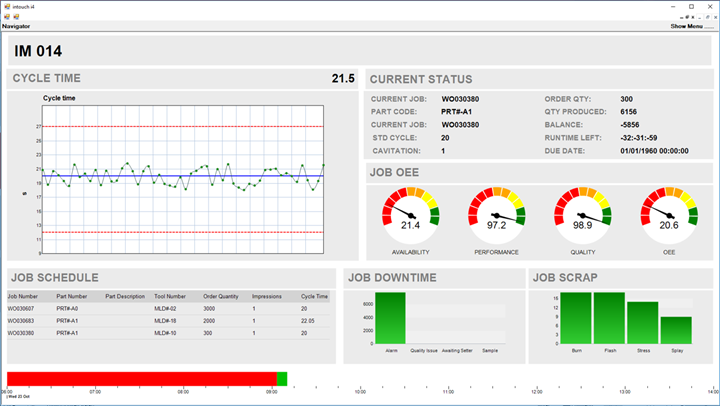

A sturdy production-monitoring platform will current an in depth overview of current and scheduled jobs and the way in which they’re performing. ({Photograph}: Intouch Monitoring.)

Actually, worth was a precedence, along with managing plenty of packages’ infrastructures; nonetheless I felt strongly ample about this technique that I decided to focus the enterprise on making use of plenty of packages, each providing the simplest choices for our plant’s requirements. As quickly as I focused the enterprise on this course, it shortly grew to turn out to be clear which process-monitoring system would meet our needs.

From the process-monitoring potential, RJG had been optimizing third-party course of monitoring for years and offered plenty of ranges of process-monitoring software program program and {{hardware}}. I invited them to present their eDart system to the crew, and whereas wrapping up this presentation they occurred to say a company in England that developed production-monitoring software program program that may run on the RJG’s eDart {{hardware}}.

Customization as Key

Intouch Monitoring gives user-interface software program program that will run on the RJG’s eDart HMI (human-machine interface). At first I was concerned that this is perhaps my argument in reverse, with regard to course of monitoring on production-monitoring packages—the polar reverse of we had been evaluating.

We invited Intouch Monitoring (intouchmonitoring.com) to our facility to present its system, and the variations between its product and the alternative production-monitoring packages have been manifestly obvious. This was a sturdy system with a singular technique.

It offered plenty of devices like job scheduler, Gantt charts, and OEE decisions, along with bidirectional communication with many ERP packages, along with the massive names inside the enterprise. Up until this degree, I had turn into considerably upset with the production-monitoring packages we had reviewed.

Particularly, I was turning into more and more concerned that there was almost no customization accessible with these packages. That would suggest that procedures should change at our facility to go well with contained in the system, and alter shall be problematic when producing parts for the medical enterprise. It’s not just because people don’t like change (as most don’t), nonetheless there is perhaps a price or a purchaser approval required, or further in all probability every.

It does not matter what system you establish on, if it is not used, it is worthless to you.

Intouch’s technique was to customize research to mimic the research that we wished to take care of, and to work contained in the procedures which were required by our purchaser. This, as so much as a result of the software program program’s potential to run on the RJG eDart {{hardware}}, supplied us on the system. So now we had acknowledged the packages that we thought supplied our best different for achievement, and I was excited that we found two packages that each specialised in a single form of monitoring. Because of they share {{hardware}}, this might alleviate a number of of those concerns talked about by completely different members of the administration crew.

Course of and Manufacturing Integration

There have been no further worries in regards to the worth of HMIs for each system, nonetheless as quickly as I started to be taught further regarding the Intouch software program program’s integration with the RJG eDart {{hardware}}, I noticed there would nonetheless be an issue with getting crew members to utilize two packages. To start a model new job, the operator should begin on the Intouch software program program after which return to the eDart side and start the job as soon as extra. Regardless that the Intouch Monitoring software program program was put in on the eDart, the Intouch software program program had no thought it was on an eDart, and the eDart had no communication with the Intouch software program program.

So, after I discussed I was concerned regarding the integration of the two packages, that’s actually because they weren’t built-in the least bit. In the middle of the primary meeting with every corporations, I made it very clear that for us to proceed, the packages wanted to be built-in, and that’s when this enterprise purchased thrilling. It was surreal working with every teams, arising with ideas and rising what would in the end turn into an award-winning, best-in-class system.

A production-monitoring system is just worthwhile if people use it. If everyone should not be ready to utilize the system, then it turns into a very pricey seen illustration of your plant floor format.

The blending on the machine was seamless. An operator would uncover the next job on the Intouch user-interface software program program, and as quickly as the start button was chosen, that job would load up in every packages. Course of templates and administration limits would autopopulate on the eDart side, and cycle necessities would populate on the Intouch side. As the mixture developed, the need to manually start a job was modified with RJG’s mold-tag {{hardware}}. As quickly because the eDart was linked to the mould’s pressure transducer or mould tag, Intouch would mechanically load the job in every packages—a high-tech handshake of two predominant monitoring corporations. The system was in the end upgraded to the aim that the machine would not start if the job wasn’t started inside the monitoring system or if the water temperature wasn’t set accurately. There could also be so much further these packages may do, and I would go on eternally, nonetheless I need to concentrate on a bit on the launch course of that we used to help promote the utilization of the system.

The Key to Success

A producing monitoring system is just worthwhile if people use it. Full stop, end of sentence. If everyone in your facility should not be ready to utilize the system, then it turns into a very pricey seen illustration of your plant floor format. These enormous screens all by means of your plant look good, however when that’s all you want, it might be carried out cheaper.

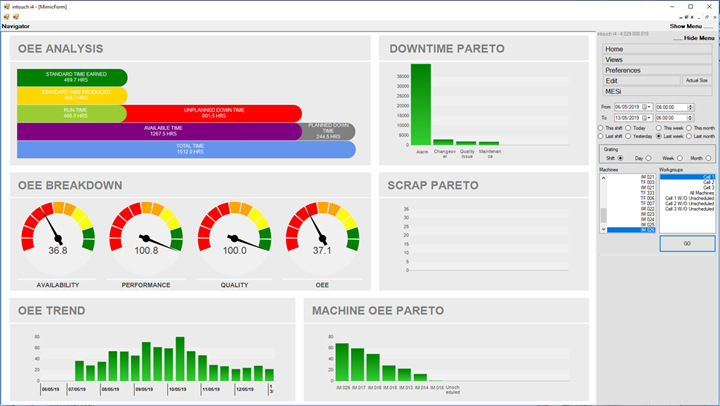

Intouch’s platform gives detailed OEE analysis and Pareto charts of key metrics like downtime and scrap.

So the massive drawback was: How can we get everyone ready to utilize this technique? First off, deciding on the right crew helps. Definitely considered one of my best takeaways from my lean teaching was the utilization of SMEs—topic materials consultants—as part of each problem-solving or continuous-improvement initiatives. Involving the crew members that basically do the work not solely helps set up true root causes, it gives these crew members possession of the choices. Choices that they will then help keep completely different crew members accountable for adhering to. Making certain this enterprise had crew members that will use the system as part of their each day obligations was key.

The next thought was to aim to affect the current procedures as little as doable, notably within the occasion that they’ve been environment friendly. It is a good suggestion for the system to be used along with procedures and research that you just’re already using. That’s an infinite one, by the way in which during which. What if the research the system generates have been to look associated, if not an an identical, to the research that crew members have been producing by hand?

This system-generated report on account of this truth is one factor everybody appears to be already acquainted and comfortable with, nonetheless we’re able to generate it in a lot much less time, with a lot much less sources, and generally it’s real-time data, so that you just don’t must attend 12 hours to go looking out out you ran 10% scrap prices. Don’t get me unsuitable: In the long term, we made many enhancements that required changes, nonetheless we made them in ranges, and we have now been able to take motion because of the system was so versatile.

We moreover tried to make changes that had as minimal an affect as doable on what the consumer required. The easiest occasion for this was the cycle checklists that the strategy techs had been ending 4 situations a day. We went as far as doing arrange qualification on each machine when the system was put in to substantiate the data was reliable, that an out-of-process shot was mechanically rejected, and that excessive rejects would quick a cycle interruption.

Regardless that we have now been now able to current proof that every half packaged off the machine was contained in the validated course of limits, the consumer nonetheless required the four-times-a-day cycle pointers. So, I challenged the Intouch crew to produce us this an identical pointers using the eDart data that is perhaps printed and despatched out with each purchaser cargo.

Since we had now completely built-in every packages, we have now been able to full this movement merchandise and liberate skilled technical sources to cope with value-added actions. This was the fulfilling side of the enterprise, nonetheless the true success of this technique was nonetheless inside the arms of the crew members that wished to utilize it on every day foundation. So how did we do it? I’ve to say it was a plan established by considered one of many founders of Intouch Monitoring. His background in manufacturing and launching the system represented a crawl-before-you-walk plan.

That seems obvious, correct? We use that phrase regularly, nonetheless whenever you spend a million {{dollars}} of your boss’s funds, see how ready they’re to look at this technique crawl to movement. It’s positively considerably more durable when you contemplate it that method, isn’t it? It wasn’t pretty that dramatic for us, nonetheless there was an extreme quantity of pressure to get it utilized, as there must have been.

First step was merely asking the crew to enter a downtime code. That’s it. Enter a downtime code each time the HMI requests one. Every morning we would observe the overall downtime and the coded downtime and speak the outcomes to the crew members. We would spend further time teaching crew members with bigger deltas, and we developed a course of transfer and course of. These course of flows and course of would in the end be combined to create the system handbook for our plant. We then purchased mould setters and course of technicians entering into their very personal downtime. Coming into the fitting downtime grew to turn out to be second nature.

A machine may very well be stopped by a course of technician for a mould change, they usually’d immediately select down for “supplies.” A material handler would change the material and immediately change the downtime to “changeover.” The mould setter would finish the mould change and alter the downtime to “course of technician,” and so forth.

Contemplate the data this supplied us to help reduce changeover situations. We’ve been able to shortly set up areas of waste all through a changeover and make enhancements. As quickly as downtime was completely mastered, we started on scrap entry classification. Each new course of may very well be mastered quite extra shortly than the earlier one, and though it might have taken considerably further time than merely flipping a swap, the outcomes have been proving to be successfully worth it.

I can say with zero doubt that caring in a enterprise like this has been considered one of many highlights of my career. Pushing all of the crew to unravel factors in order so as to add efficiency to this technique—which in the intervening time hadn’t been carried out sooner than—after which seeing it work was very rewarding. I’m optimistic there is a degree the place the Intouch crew was sick of listening to me say, “I need it to (insert unreasonable request proper right here)—when can you have acquired it ready?” Or having the RJG crew take a look at me like a madman after I requested them to indicate {{that a}} brand-new cavity-pressure transducer may very well be right, nonetheless then have them shock me plenty of weeks later with transducer verification instruments. These packages shall be tremendously worthwhile and should current exhausting buck monetary financial savings. An important drawback shall be getting everyone to agree on a system, and usually you merely should thank everyone for his or her enter—and you then determine.

ABOUT THE AUTHOR: Robert Gattshall has better than 22 years’ experience inside the injection molding enterprise and holds plenty of certifications in Scientific Injection Molding and the devices of Lean Six Sigma. Gattshall has developed plenty of “Most interesting in Class” Poka Yoke packages with third-party manufacturing and course of monitoring resembling Intouch Monitoring Ltd. and RJG Inc. He has held plenty of administration and engineering positions all by means of the enterprise in automotive, medical, electrical and packaging manufacturing. Gattshall may also be a member of the Plastics Enterprise Affiliation’s Public Protection Committee. In January 2018, he joined IPL Plastics as course of engineering supervisor. Contact: (262) 909-5648; rgattshall@gmail.com.